Inventor

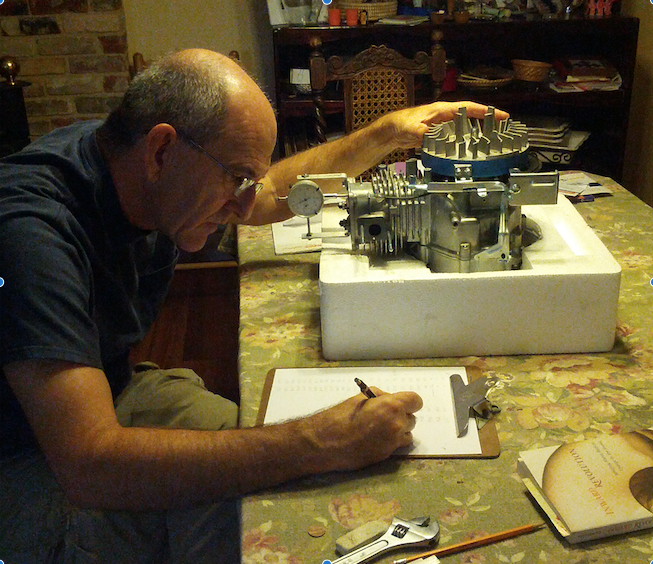

Fascinated with the steam engine, Mike Brickley designed and built a steam powered bicycle while in high school. Interest in other types of heat engines followed, each with its accompanying acquired knowledge base. A breadth of disciplines including thermodynamics, engineering design, and hands-on machine tool experience as each applies to the steam engine, the stirling engine, and the internal combustion engine, allowed for an unusual way to view the problem of engine friction. Based on this knowledge history he created the design for the Brickley Engine and has now completed a proof of concept engine. He designed and machined both the tooling and the majority of the parts himself. He has been granted three U.S. patents for the engine design.