Austin, Texas, USA■

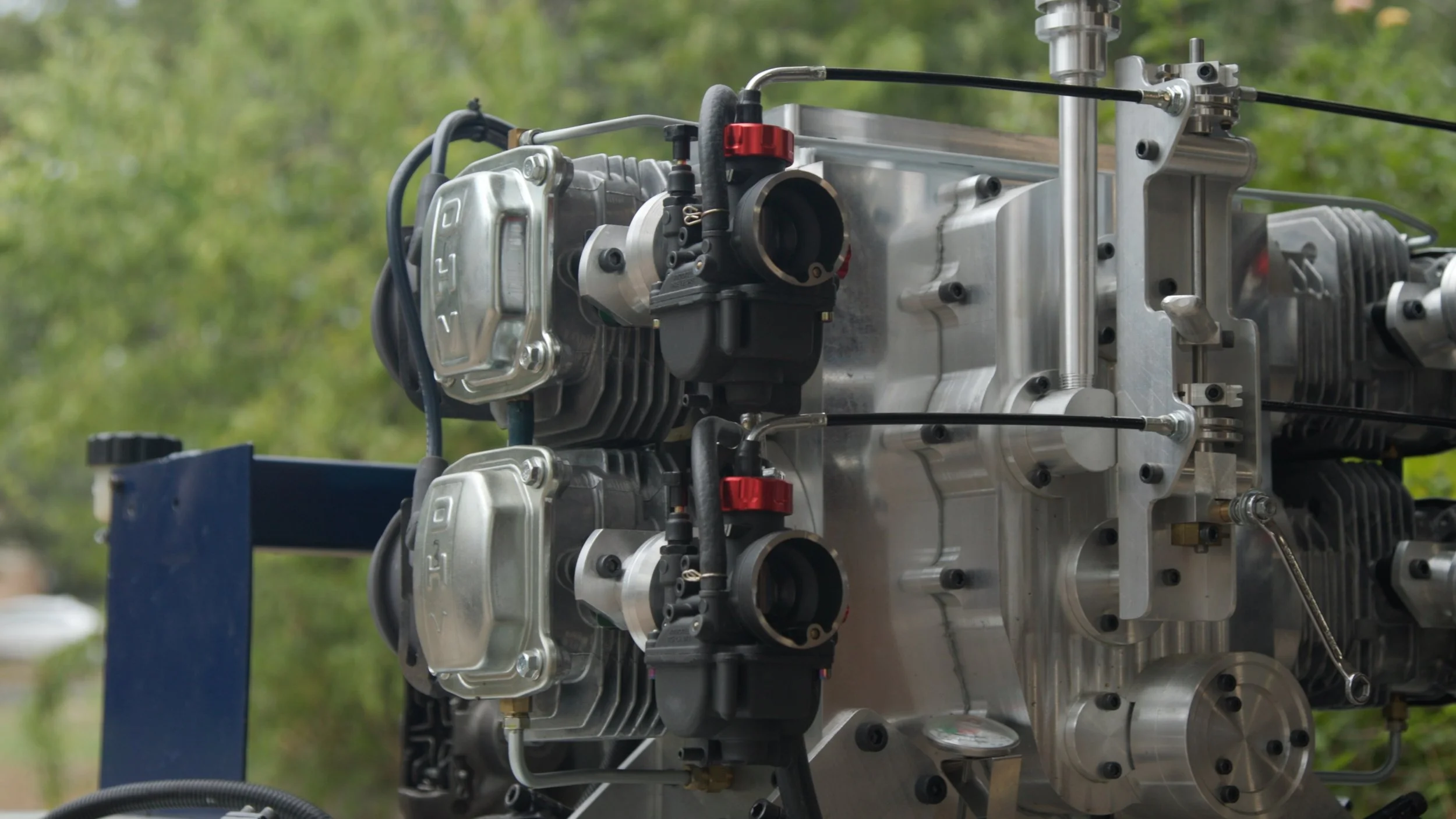

With ~50% less friction than a typical in-class engine, the Brickley Engine offers an unprecedented 25% reduction in both fuel consumption and CO2 emissions in an overall lighter, more compact package.

[ About ]■

Drawing on decades of hands-on engineering experience and deep technical and conceptual understanding, Mike Brickley has re-designed the bottom end of the internal combustion engine to deliver a platform for a new era of IC engines.

[ Summary of Advantages ]

-

By reducing bearing travel, using fewer bearings that rotate 360°, and eliminating the need for piston skirts, the Brickley Engine reduces the overall distance where friction occurs by about one-half.

-

Less friction means greater efficiency, and with that greater efficiency comes a fuel savings of 25%.

-

The 25% reduction in fuel consumption means that this is also the fraction by which emissions are reduced.

The Story

Meet Mike

Fascinated with the steam engine at an early age, Mike designed and built his first steam-powered bicycle as a high school student. As he pursued a degree in Mechanical Engineering, an interest in other types of heat engines, along with their accompanying knowledge bases, followed naturally.

According to Mike, it was this breadth of disciplines, including thermodynamics, engineering design, and hands-on machine tool experience (each having relevance to steam, stirling, and internal combustion engines) that allowed him to view the problem of engine friction through an innovative lens.

It was based on this knowledge and insight that he conceived of the design concept and later designed, machined, and built the proof-of concept Brickley Engine. He has been granted three U.S. patents for the engine design.