Testing

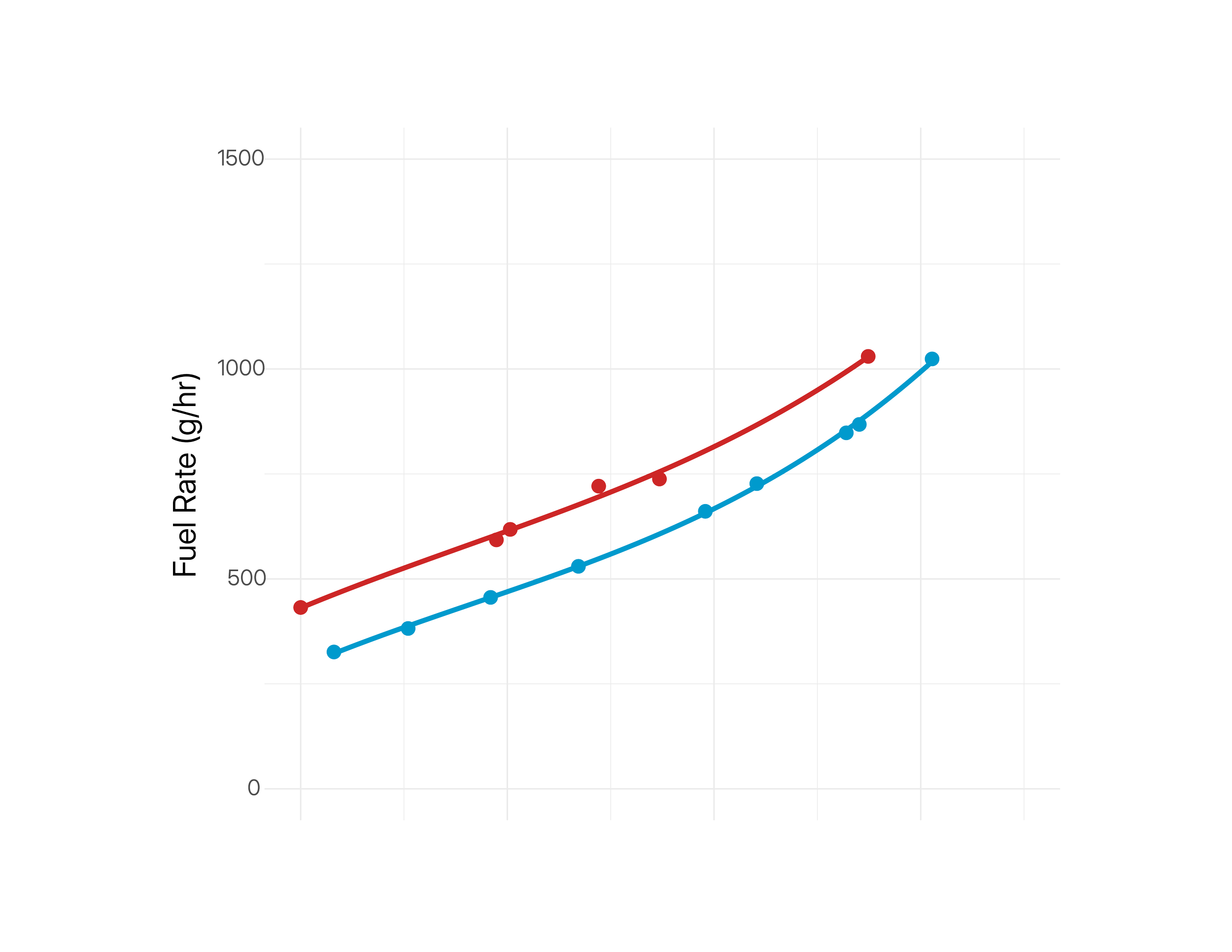

The Brickley Engine, represented here in blue, shows consistently lower rates of fuel consumption across a range of power outputs when compared to its counterpart, the 173cc Predator engine, shown in red.

As the Brickley Engine is a four-cylinder engine and the Predator is a single-cylinder engine, the Brickley Engine fuel rates shown to the right were obtained by dividing the overall fuel rate of the Brickley Engine by four to arrive at a single-cylinder fuel rate; both engines were tested using aftermarket Nibbi PE Carburetors at 3000 rpm.

The fuel savings offered by the Brickley Engine vary according to throttle position, ranging from 30.5% at “no load” to 13.9% at full throttle, with no load equivalent to the engine at idle. The 25% reduction in fuel consumption occurs when the throttle is approximately 16.7% open, or 1/6 load, which is a common benchmark for fuel consumption readings.

The rates shown here are simply the numerical differences in fuel consumption shown in the graph above but expressed here in terms of percentages.

Third-party friction tests on the Brickley Engine were performed by ROUSH Industries, Inc, at their facilities in Livonia, MI, just outside of Detroit.

NOTE: The friction tests performed by ROUSH Industries, Inc., were privately commissioned and should not be construed or interpreted as endorsement of any other claims regarding the Brickley Engine.

Third-Party Friction Tests

Before the Brickley Engine was built and tested, the projected friction reduction was estimated by simply adding up the total distance over which oil would be sheared inside the engine—that is, the distances associated with bearing travel, piston skirt travel, and the travel of other components.† In comparing these totals with the sums associated with traditional configurations, it was seen that the Brickley Engine configuration reduces the total friction by roughly 50%.

After the proof of concept engine was built and tested in house, third-party friction tests for the Brickley Engine were commissioned, and they returned a Friction Mean Effective Pressure, or FMEP, of 31 kPa.

Although the literature does not seem to include a perfect, similarly spec’d engine with which to make a straightforward comparison of FMEP values, there are engine data within the literature that, when taken together, provide more than enough context to suggest that the Brickley Engine’s 31 kPa measurement is, conservatively, 50% less than a typical in-class engine.

In the bar chart above, the 2.5L Ford Duratec engine (Sethu et al., 2007) differs from the Brickley Engine in that it is a 6-cylinder engine instead of a 4-cylinder, it’s a little over three times as large, and it has an FMEP of 61 kPa. In order to compare these two engines, it’s important to first note that the FMEP is based on an engine’s total displacement and not on the total number of cylinders. While the number of cylinders can affect the FMEP slightly, the greater determinant of FMEP in similar engines is displacement. As shown in Soltic (2000), a reduction in displacement of one-half results in a 10% increase in FMEP. This suggests that if the Ford Duratec V6 engine were to be scaled down to the displacement of the Brickley Engine, it would likely have an FMEP of more than 70 kPa. In this case, a reduction of 39 kPa, from the Duratec’s 70 kPa to the Brickley Engine’s 31 kPa, would be a 55% reduction in the total friction.

† When the components of an engine are properly lubricated, the bearing surfaces technically never touch; instead, the oil that separates the surfaces is sheared. Thus, the friction inside the engine can be generally associated with the distance over which oil is sheared.

FMEP tests for the Brickley Engine and the Ford Duratec V6 were performed at 1500 rpm.

References & Resources

Aoki, K., Kuroda, S., Kajiwara, S., Sato, H., & Yamamoto, Y. (2000). Development of integrated motor assist hybrid system: development of the'insight', a personal hybrid coupe. SAE transactions, 1883-1890.

Mufti, R. A. (2004). Total and component friction in a motored and firing engine (Doctoral dissertation, University of Leeds).

Pipitone, E. (2009). A new simple friction model for SI engine (No. 2009-01-1984). SAE Technical Paper.

Sandoval, D., & Heywood, J. B. (2003). An improved friction model for spark-ignition engines. SAE transactions, 1041-1052.

Sethu, C., Leustek, M. E., Bohac, S. V., Filipi, Z., & Assanis, D. N. (2007). An investigation in measuring crank angle resolved in-cylinder engine friction using instantaneous IMEP method (No. 2007-01-3989). SAE Technical Paper.

Singh, A. (2013). A friction prediction model for small SI engines. (Master’s thesis).

Soltic, P. (2000). Part-load optimized SI engine systems (Doctoral dissertation, ETH Zurich).

Sylvester, J. R. (2012). Characterization and modeling of rubbing friction in a motored four-cylinder internal combustion engine (Doctoral dissertation).